Well P&A is showing a steady increase in reported numbers of technologies in 2024, from a low base in 2020.

Innovation is driven by both vendors and operators and includes through-tubing logging, barrier placement, and downhole wireless sensing,

There has been progress in introducing novel barrier materials and deployment techniques, and tools for removing control lines from downhole gauges.

Modular workover rigs for platforms and light well intervention vessels for subsea abandonments can lower P&A costs when compared to the use of standard rigs.

- Continuous growth in number of technologies for Well P&A as more decommissioning programmes get underway

- Key areas of innovation cover alternative barrier materials and their placement, and intervention equipment able to reduce time and cost of P&A operations

- Interest in P&A innovation appears concentrated with 17 Operators who have reported technologies in their Plans

Well P&A is a field of active innovation with about 50% of technologies reported in Operators’ Plans noting recent introduction or technology still under development

There is a significant participation by Operators in driving improved practices in partnership with vendors and service companies

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

This is an area with a number of tools developed to assess the well bore, downhole leak paths, and logging cement tops and cement condition (including multi string applications). There are several emerging technologies including multi string logging for barrier verification and assessing cement quality behind the production casing.

- Acoustic tool - for detection of gas leak paths downhole.

- TRL 9 Commercially Available

- Multi string isolation logging tool – to allow cement tops to be logged in multiple casing strings

- TRL 9 Commercially Available

- Inside casing status visualisation technology - gave very good resolution of inside casing status.

- TRL 9 Commercially Available

- Retrofit fibre optics to inspect the well bore - deployed on Fibreline to review well bore.

- TRL 9 Commercially Available

| Technology Example: | |

|---|---|

|

Well Sense FLI tools - length of fibre unspooled from a FLI probe to 7,715m. Active-FLI probes, fitted with electronic sensors and optical telemetry. FLI is primarily designed to be a distributed sensing system, observing the wellbore simultaneously along the entire length of the unspooled fibre. |

|

- Multi string logging tool – to assess cement through multiple strings by through-tubing logging

- TRL 8 Early Commercialisation

- Acoustic, Gamma ray & Electro Magnetism Through Tubing Logging - Multi string logging for barrier verification being tested in wells

- TRL 5-7 Late Development/Pilot

- Alternative cement logging tool- Tool for through tubing logging to assess cement quality behind the production casing.

- TRL 5-7 Late Development/Pilot

There are several examples of conductor cutting techniques reported this year with one operator confirming deployment of a combined hydraulic cutting tool with a pinning tool to allow combined cutting and pinning operations

- Hydraulic severance of conductor and casing strings- using Hydraulic conductor Cutter.

- TRL 9 Proven Technologies

Control Cutter - Conductor Decom Package includes all equipment and calculations required to recover the wellhead and conductors. Multistring casing is sectioned into the required lengths prior to lifting, handling and preparing the sections for backloading. Cutting and pinning tooling is incorporated into a single interface frame/table.

- Abrasive water jet cutting tool – For conductor recovery

- TRL 9 Proven Technologies

- Wellhead Cutting Tool – Controls all cutting parameters, including verification of a completed cut. The system is based on a diamond wire technique removing the need for compressed air, and combined with a smaller spread, requires with fewer personnel on board.

- TRL 1-4 Early development

Operators are using deployable technologies such as through tubing abandonment, ongoing field trialling of non-alloy barriers, fusion based alloy plugs, suspended well abandonment tools for rigless abandonment using lower cost vessels and an operator plans to use self-healing cement to incorporate downhole gauge cables which prevent effective plug setting. Emerging technology is being progressed through trials of novel abandonment techniques.

- Computer modelling to justify reduced or risk-based isolation strategies - Utilisation of existing reservoir management software to enable simulation of potential flow of hydrocarbons (including cross flow) through identified leak paths.

- TRL 9 Proven Technologies

- Agitator tool - Wireline run tool set in completion string excites tubing while pumping to enable effective 360 deg. placement of cement.

- TRL 9 Proven Technologies

- Suspended Well Abandonment Tool - Allows well abandonment via DSV without having to mobilise a rig. Tool is able to perform perforation, circulation, and cementation of multiple casing annuli in single / multiple runs while maintaining appropriate pressure control barriers.

- TRL 9 Proven Technologies

Rated to 5000 psi, Claxtons SWAT is capable of being deployed from any dynamically positioned vessel, landed on the wellhead and then used to carry out casing perforation, followed by clean up and placement of the required cement barriers in the well.

- Self Healing Cement - can be used to incorporate gauge cables in the abandonment barrier.

- TRL 9 Proven Technologies

- Non- Alloy barriers for LWIV subsea well P&A - Viscous gel plug as base for setting tubing and annular cement barrier in subsea well allowing LWIV only abandonment

- TRL 9 Proven Technologies

- Perf & Wash and Punch & Wash – technologies which may provide savings compared to section milling when conducting remedial work.

- TRL 9 Proven Technologies

- Fusion based alloy through tubing abandonment – Multiple Operators considering various fusion base alloy barriers

- TRL 8 Early Commercialisation

- Bismuth plug - Surface controllable bismuth plug used as an alternative to cement material. Potential utilisation to allow offline environmental caps to be placed without a rig.

- TRL 5-7 Late Development/Pilot

- Shale barrier predictions - Pseudo DCM analysis to predict abandonment barriers from conventional log data

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- E&A trial of pure bismuth annulus barrier installation, non fusion - relies on friction fit to prevent creep of the plug once a pressure differential is created. Aims to restore the primary barrier in the annulus

- TRL 5-7 Late Development/Pilot

Operators are considering light well intervention vessels for subsea open-water abandonments and subsea shut-off devices for open-water tubing retrieval. Emerging technology includes novel approaches for breaking the cement bonds on casing strings. New this year are the swarf recovery unit and a casing recovery system.

- LWIV subsea well abandonment - Open hole 300' tubing cut, recovery and layout on seabed for subsequent uplift by CSV allows LWIV only subsea well abandonment

- TRL 9 Proven Technologies

- Subsea open water P&A - Through-tubing P&A with an LWIV. Includes recovery of tubing hanger and surface tubing to allow setting of environmental plug.

- TRL 9 Proven Technologies

- Magnetic separation and recovery unit - Swarf Recovery unit

- TRL 9 Proven Technologies

- Casing Recovery System - Uses pressure and rotation to manipulate the casing string, breaking down the bond between cement and casing making it easier to remove casing quickly and efficiently. Can reduce operation time from 25 days to 12.5 days

- TRL 8 Early commercialisation

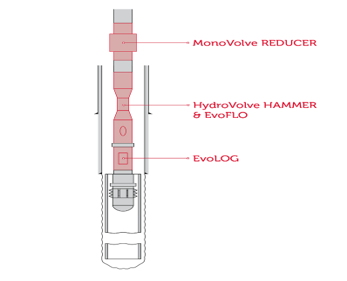

- Jarring technology - Combines high overpull forces with high frequency vibration to improve stuck-object extraction force

- TRL 8 Early commercialisation

HydroVolve Hammer – combined pulling and impact forces to break settled solids and shear cement bonds. Combining high overpull forces with high frequency vibration to deliver stuck-object extraction force to remove stuck casing.

- Subsea Shutoff Device (SSD) & Volume Control System (VCS) - SSD allows the well to be secured for open water tubing retrieval. VCS allows for early detection of volume/pressure changes in the well when retrieving tubing in open water.

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Explosive severance tool - Technology to simultaneously sever all necessary casings to allow recovery of subsea wellheads. An explosive charge is deployed internally within the casing(s) to be severed, severing up to four strings of fully cemented concentric casings, from 9-5/8” to 30” x 1.5”

- TRL 9 Proven Technologies

- Casing cement breaker - Mechanical device to manipulate a casing string to break the cement bond between casing and cement or barite and facilitate deep casing recovery.

- TRL 5-7 Late Development/Pilot

- Cable retrieve tool - For wells where a downhole pressure and temperature gauge exists the power cable is strapped to the outside of the production tubing and runs across the interval in the well where an abandonment barrier would be placed. The gauge cable can reduce the effectiveness of cement barriers.

- TRL 5-7 Late Development/Pilot

The AxterReach locates and retrieves a line (control line, tube encased cable, wireline cable and similar) from a wellbore. The AxterReach handles P&A as well as fishing operations.

Included this year are innovative solutions for improving well access for interventions, low-cost platform workover rigs/modular drilling rig systems, rigs specifically configured for well P&A, and riserless P&A systems. New this year are an inside casing status visualisation technology , subsea vessel based fishing tools and a casing expander tool.

- Vessel based fishing tools - Use of vessel based subsea technology to remove debris to allow abandonment

- TRL 9 Commercially Available

- TRL 9 Commercially Available

- Casing expansion tool - Method for creating base in annuli to assist with fluid segregation to improve quality of cement jobs / stop fluids swapping.

- TRL 9 Commercially Available

- TRL 9 Commercially Available

- Rig configured specifically for well P&A – to deliver transformational subsea well P&A with rig designed for specific purpose (multiple solutions by vendors)

- TRL 9 Commercially Available

Deployed from a dynamically positioned monohull vessel, the Riserless Well Intervention System (RWIS) provides a reliable solution for carrying out cost-effective intervention and abandonment operations on all types of subsea wells. The RWIS is modular in design, allowing the system to be tailored to specific job requirements

- Cement restoration tool - to restore cement behind casing

- TRL 9 Commercially Available