Operators continue to focus on cost-effective installation solutions to support development of more marginal hydrocarbon resources:

- Subsea energy generation and storage systems with integrated subsea controls have potential to restore lost production when subsea umbilicals fail .

- Subsea processing and boosting for long distance tie-backs

Emission reduction technologies:

- Onshore smart rooms for remote operations

- Hybrid power systems, waste heat recovery

- Fugitive gas leak monitoring of valves and pipework

- Flare combustion efficiency monitoring

- Flare gas recovery

- Vapour recompression to capture flash gas

Installations & Topsides technologies

197 technologies related to design and equipment for surface installations were reported in 2024, the second largest category after Facilities Management.

Operators’ focus includes

- process equipment able to cope with more complex fluid compositions

- facilities monitoring and remote operations

- increasing attention on power efficiencies and emission reduction

11 Operators carry at least 5 Topsides technologies in their current Plans, and 13 more Operators report at least 1 technology

Operators focus on Proven Technologies, but with nearly 30% of technologies still in Pilot or Early Commercialisation stages

Industry relies on Vendors to source technologies for new facilities and facility upgrades

Operator-vendor partnerships are also common to address specific facility requirements green-field projects and asset upgrades, and the offshore emission reduction targets

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Operators are focusing on intelligent plant analysis, retrofit gas turbine controls, use of AI and machine learning for analytics and event detection, and DCS and automated control systems. Also upgrading control systems and installing cloud-based upgrades to receive live stream data from offshore. New this year are re-instrumentation of Christmas trees, production monitoring and upgrade of alarm insights systems.

- Production monitoring models at asset level - Rate independent monitoring of heat exchangers and vibration. monitoring

- TRL 9 Commercially available

- Well & Flowline Connectivity - Complete re-instrumentation of Christmas trees and flowlines to allow reliable, remote visibility of valve positions, pressures and temperatures and better shutdown functionality.

- TRL 9 Commercially available

- TRL 9 Commercially available

- ESD HMI Upgrade - Upgrade existing system to improve control room operator platform shutdown response and control.

- TRL 9 Commercially available

- Alarm Insight System - Upgrade for improved functionality

- TRL 9 Commercially available

- Retrofit gas turbine controls - Retrofit gas turbine controls plus removing obsolete items on package. More feedback into control system - provides greater feedback loop. Can add parts that move components for preservation reasons

- TRL 9 Commercially available

- DCS upgrade - The Operators FPSO DCS system currently comprises a mixture of Process Controllers, together with associated IT/coms infrastructure and interfaces to other ICSS systems. Operator is undertaking a brownfield change-out / upgrade to address these issues

- TRL 9 Commercially available

- Control system upgrades - Replacement of obsolete, disparate control systems on Operators asset with a single, modern DCS.

- TRL 9 Commercially available

- Automatic Control System (ACS) – Automation of ESP operations, automated control systems to operate ESP’s Automatically.

- TRL 9 Commercially available

Automatic Control Systems –ABB Automated Control system for ESP’s

- Cloud-based PI system - Deployed the PI system in the azure cloud-based system to receive the live data stream from offshore and ingest data from the morning report

- TRL 9 Commercially available

- Machine learning software - Proof of concept that machine learning can highlight areas for improvement and potential diagnose very early event detection

- TRL 1-4 Early Development

Operator focus remains on a small number of technologies including chemical dosage testing, produced water re-injection, and diluent optimisation/minimisation technologies. Although the number of individual technologies is small, some are used on multiple assets.

- Diluent optimisation/minimisation - Increase topside export pressure to facilitate crude cold start-up, minimising diluent usage and maintaining crude export pipeline flow assurance.

- TRL 9 Commercially available

- Corrosion Inhibitor Dosage System - "A technology that provides information on optimal dosage of corrosion inhibitors by measuring micelle concentration. Benefits include increased asset integrity, reduced pipeline inspections, potential chemical cost reduction."

- TRL 9 Commercially available

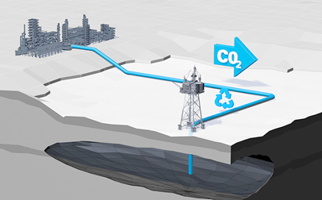

- Produced water re-injection - Produced water reinjection, (NSTA information - PWRI) is a method for eliminating the environmental impact of discharging produced water at offshore oil production sites. Reinjection of produced water has been carried out on several locations around the world. In most cases the activities have been concentrated on individual wells and have not included mixing the produced water with seawater prior to injection).

- TRL 9 Commercially available

Operators' technology plans show a greater uptake of flare gas and flash gas recovery technologies including membrane and compact separation systems. More efficient valve technologies, liquid ring compressors for flare gas recovery, and technology to decelerate scaling/fouling of topsides process equipment are also reported. New for 2024 is microbubble injection.

- Brownfield flare gas recovery - Brownfield deployment of flare gas recovery units with a view to meeting zero routine flaring commitments

- TRL9 Commercially Available

- Flare gas recovery to achieve zero flare gas emission - Develop a safe flare recovery system to recover flare gas, minimise CO2 emission, and reduce import gas usage.

- TRL9 Commercially Available

A flare gas recovery unit (FGRU) is a system that captures flare gases and redirects them back into production workflows for reuse as fuel gas. This process helps to reduce routine flaring and emissions while saving operators on long-term production costs.

- Enhanced Oil/Water separation - Electrostatic coalescing technology that is installed inside an oil/water separator

- TRL9 Commercially Available

- Eductor Vapour Recovery - Reduce the CO2 footprint from Flaring of process flash gas. Use of the latest Eductor Vapour Recovery Compression tech to capture flash gas to reduce flaring.

- TRL9 Commercially Available

- Low Shear Valves - Control valve that minimizes mixing energy. Inline and angle type. Leaves droplets intact to improve performance of subsequent separation / treatment.

- TRL9 Commercially Available

- TRL9 Commercially Available

- Liquid Ring Compressors - For Flare Gas Recovery, uses a liquid ring formed from the operating liquid, instead of a mechanical piston to compress gases and vapors

- TRL 9 Commercially Available

-

Microbubbles - injection upstream of the degasser to enhance oil in water separation and therefore improve discharge performance

-

TRL 8 Early Commercialisation

-

-

Ceramic based static / passive membrane filtration system - A commercial ceramic based static / passive membrane system, which will allow offline oil removal from produced water.

-

TRL 8 Early Commercialisation

-

- Stemless Valves - Axial flow stemless valves could remove fugitive emission and the reliability and integrity issues associated with a conventional valve. Also, they may reduce flow-induced instability in some services .

- TRL 8 Early Commercialisation

- Anti-scale technology - Technology being trialled to determine whether it decelerated scaling/fouling of topsides process

- TRL 8 Early Commercialisation

- Chemicals to manage heavy/light oil mixture - Developing a new family of chemicals, which the aim of combating a unique issue of mixing existing light oil with a new heavy oil tieback.

- TRL 5-7 Late Development/Pilot

- Super compact production separator - Working with the Net Zero Technology Centre to develop a super compact multi-phase separator with potential to add value across full asset life cycle.

- TRL 5-7 Late Development/Pilot

Operators' technology plans for 2024 show digital twin technology being applied in new ways for hull fatigue external structure modelling and new valve technology for TEG systems. New this year are high speed internet connections for FPSOs, 3D sonar scanning modelling of process systems, and integrated Activity Integration Workbench software to combine 3 proprietary softwares for an integrated view to visualise and performance manage at site.

- High speed internet connection on FPSO - serving as primary connectivity channel for both operation and recreation use.

- TRL9 Proven Technologies

- Cylindrical FPSO - Adopt cylindrical FPSO design for operators project to remove the need for turret and enable project to be economically feasible

- TRL9 Proven Technologies

- Integrated data package AiW Application combines data from the 3 core systems to provide users with an integrated view of what’s needed to execute and performance manage work at site.

- TRL 9 Proven Technologies

- 3D Sonar Scanning - Use of 3D Sonar Scan modelling of process system for implementation of integrity workscopes

- TRL 9 Proven Technologies

- Methane Sensor attached to Unmanned Aerial System (UAS) - Methane emissions survey conducted using drone flight survey. Gathering of baseline data in support of methane action plan

- QTRL 9 Proven Technologies

- 3D photogrammetry model of external structures using drone technology on FPSOs

- TRL 8 Early Commercialisation

- Diverless I-Tube integrity scans - the subsea team together with a selected vendor developed a diverless method by constructing multiple sleeves that join and fit into the I-Tube that can incorporate a UT and scanning tool. This will be dropped down the I-Tube and sleeves will bridge the gap between the upper and lower I-Tubes allowing the tool to reach that un-accessible section to carry out the scans.

- TRL 5-7 Late Development/Pilot

- IMI-CCI Valve tech for contaminated fluids treatment - Installation pilot project on an FPSO. The new valve design in the TEG contactor system allow large pressure drop at low flow for solid contaminated fluids treatment.

- TRL 5-7 Late Development/Pilot

Reported this year are adoption of NII technologies including for hard-to-reach inspection of cargo tanks, use of remote UT and sensor arrays, and deployment of predictive analytics to improve production efficiency, caisson cleaning & inspection tools, high frequency radar level detectors for drains vessels and improved broadband comms links. New this year are digitalisation of maintenance execution with 3D tablets & visualisations, 3D digital twins of offshore installations and supply vessels for real time management of deck layout and loads. Emerging technologies are AI LOFEO modelling, inventory optimisation tool, plant availability diagram tool and real time equipment/system availability status tools.

- Digitalisation of maintenance execution - Use of tablets and 3D visualisation to speed up maintenance execution and reduce POB

- TRL 9 Proven Technologies

- Offshore Installation and Supply Vessel Deck Optimisation - 3D digital twin of offshore installation and vessel to allow real time management of deck loads

- TRL 9 Proven Technologies

- Inspection tools and platforms - to reliably inspect cargo oil tanks in service, eliminating confined space entry for inspectors and increasing production efficiency by avoiding production slowdowns and shutdowns

- TRL 9 Proven Technologies

- IRIS Upgrade - Updated Incident reporting system including action tracking and learning

- TRL 9 Proven Technologies

- Predictive Analytics for Plant Monitoring - Use of a third party vendor using data to improve plant efficiency / prevent trips

- TRL 9 Proven Technologies

- Splashzone Scanner - Externally deployed caisson cleaning and inspection tool. Also has potential for conductor inspections to help justify removal strategy.

- TRL 9 Proven Technologies

- Remote UT & sensor Array - Reduced/removed requirement for Corrosion Coupon removal every 6 months Circa £40K per year saving. Removed requirement for Break containment permits.

- TRL 8 Early Commercialisation

- High frequency radar level detector - Reliable level measurement in drains vessel - level detector which does not require guidance tube which is susceptible to blocking up.

- TRL 9 Proven Technologies

- AI LOFEO modelling - Utilise AI modelling for LOFEO safety conversations

- TRL 5-7 Late Development/Pilot

- Neutron Backscatter Inspection for CUI - we sought to develop a screening method to identify areas of insulated pipework most susceptible to CUI (i.e. those with presence of water in lagging). Neutron backscatter tool deployed during 2018. this includes review of value associated with Neutron Backscatter tool.

- TRL 5-7 Late Development/Pilot

- Platform Electrification - New cable installed to import available power reducing requirements for diesel or gas generation.

- TRL 1-4 Early Development

- TRL 1-4 Early Development

- Plant Availability Diagram – New equipment / system availability status tool to show what's available/operational in real time

- TRL 1-4 Early Development

- TRL 1-4 Early Development

- Inventory Optimisation - Automated inventory optimisation and reporting tool

- TRL 1-4 Early Development

Operators' technology plans for 2024 continue to show operator focus is on more sophisticated methods of emissions monitoring including use of AI, and improved detection methods. New this year are 3 phase virtual metering and autonomous methane measurement using fixed FLIR cameras.

- 3 Phase Virtual Metering - Fully nodal (no reservoir model) metering technology suitable for new fields or wells. Accommodates changes in reservoir pressure and in PI captured data.

- TRL 9 Commercially available

- TRL 9 Commercially available

- Predictive emission monitoring & streamlined reporting to improve accuracy of emission reporting from combustion plant and flare

- TRL 9 Commercially available

ABB PEMS to improve efficiency and streamline emissions reporting. ABB offer the PEMS solution

- NIR Spectral Analysis offshore - Lab studies and field trials to establish the potential to utilise NIR Spectral analysis characterisation of production stream crudes for hydrocarbon characterisation, stream allocation and cell stock management

- TRL 9 Commercially available

- Virtual Metering -Use of flow computation/totalising in Fiscal and Allocation metering systems which lowers lifecycle costs. Already been carried out on some metering awaiting approval for use on Fiscal metering.

- TRL 9 Commercially available

- Oil Metering Upgrade - Upgrade of 3 operators assets oil metering to 32-path M&T DFX Ultrasonic Flow Meters to improve accuracy.

- TRL 9 Commercially available

- Methane Emission Surveys - Use of remote systems e.g. fixed wing or drones to collect data on unburnt hydrocarbons/methane and fugitives

- TRL 9 Commercially available

- TRL 9 Commercially available

- AI for Emissions Reduction A digital solution that helps carbon intensive companies to overcome these challenges, decarbonise their operations and reduce emissions, energy and fuel costs.

- TRL 9 Commercially available

- TRL 9 Commercially available

- Flare combustion efficiency modelling - Cloud based solution which calculates flare combustion efficiency using existing data (flare flow rates, gas composition, weather data etc.).

- TRL 8 Early Commercialisation

- Autonomous Methane Measurement - Measurement of methane emissions from unburnt fuel gas, unburnt flare gas, venting and fugitives.

Use of ATEX rated autonomous measurement device to detect and quantify baseline methane emissions and abnormal events using TDLAS measurement technique.- TRL 5-7 Late Development/Pilot

Growing adoption of low carbon power technologies including waste heat recovery, wave energy generation, and lean direct injection for gas turbines. New this year are fuel cell power generation, solar power systems, hydrogen ion splitting, battery storage, capacitive transfer cable systems, and e-methanol low carbon fuel.

- Fuel Cell power generation – Installation of 600kW fuel cell technology to produce electricity from imported gas with minimal emissions and high efficiency

- TRL 9 Commercially available

- Photovoltaics - Solar power system - Power generated using photovoltaics arranged in arrays. Power output proportional to incident light intensity – highly seasonal.

- TRL 9 Commercially available

- SMC Battery Technology - High failure rate of VRLA battery technology due to high ambient temperatures. SMC technology has a secondary benefit of reducing the footprint and weight up to 2/3 vs existing technology

- TRL 9 Commercially available

- Helix Wind turbine – Adding a wind turbine to a Hybrid Power System to reduce the running hour of the back-up diesel generator

- TRL 9 Commercially available

- Hybrid power system - Hybrid power system providing a maintenance free solution in the form of solar panels, providing power to the platform whilst charging batteries. Two small lean-burn diesel-engine driven generators will provide energy in case the renewable system fails.

- TRL 9 Commercially available

- Platform Electrification (Power Supply) - Development of grid tie-in, conversion of AC to HVDC for transmission in a subsea HVDC cable to an offshore sub-station

- TRL 9 Commercially available

- Hydrogen Fuel Cell Generator - Power is generated from a process of splitting pressurised hydrogen into positive ions and electrons – flow of electrons is used as power.

- TRL 8 Early Commercialisation

The R&D carried out by the EODev and Toyota teams has enabled the REXH2 to be perfectly adapted to the extreme conditions of the marine environment, reaching power levels of 70 kW per unit, up to megawatts when stacked.

Technology example link

- Wave Energy Convertor - Innovative system for generating electricity from ocean waves

- TRL 9 Commercially available

- Electrification of Asset via Floating Wind Solution – Partial/full electrification of asset with a floating wind power source

- TRL 8 Early Commercialisation

- Capacitive Transfer System - New capacitive cable system design with aims to reduce cable power losses by 10% allowing for smaller cables with lower losses

- TRL 5-7 Late Development/Pilot

- E-Methanol - Generating low carbon fuel offshore in an economical and safe way

- TRL 5-7 Late Development/Pilot

- WHR to Power- Currently all the waste heat from the simple cycle GTs goes to the atmosphere that could potentially be used to generate electrical power. the challenge do this economically on a brownfield asset. Vendor hopes that this may be a compact engine to economically deploy offshore.

- TRL 5-7 Late Development/Pilot

Operators report novel personnel access systems such as dedicated walk to work vessels and small-scale renewable power packages. New this year are 3D mapping of unmanned facilities to reduce the need for offshore trips and remote leak detection technologies. Emerging this year are asset automations and NUI conversions.

- 3D Mapping - 3D mapping of platforms using a laser scanner to photograph and map all areas providing sufficient precision to support surveys for installing new equipment. It also allows a small window to conduct visual integrity inspections, thereby reducing personnel on the platform and hence risk to personnel.

- TRL 9 Commercially available

- Leak detection and Performance testing – of main export riser valve despite lack of good proven isolations on a number of other valves locally making it difficult to find which valve is actual passing. Reduces the requirement for expensive high-risk break of containment.

- TRL 9 Commercially available

- Hydrocarbon leak detection camera - Surveys have been complete to capture fugitive emissions offshore, capturing early failure or confirming no leaks are present.

- TRL 9 Commercially available

- Renewable Power Package - Installation of renewable power package allowing for emissions reduction and less maintenance/intervention.

- TRL 9 Commercially available

- Walk to work - heave compensated platform - Use of walk to work technology utilising a heave compensated platform sited on the back of a surface vessel to provide an alternative means of accessing the platform or SPM.

- TRL 9 Commercially available

- Asset Automations and NUI conversions - Asset simplification and remote control from onshore terminal.

- TRL 1-4 Early Development