Notable technology areas in Subsea include:

- Remote and autonomous inspection technologies able to reduce the number of offshore visits and manned interventions.

- Design advances include vacuum insulated tubing for subsea HPHT tiebacks, and progress in subsea processing and pressure boosting.

- Greater use of advanced analytics and AI in many areas, from controls to inspections

Subsea Systems technologies

Operators’ technology focus spreads across design, installation and operational phases of the subsea systems

Advances in pipeline design, and more capable subsea processing equipment enable more distant and cost-effective subsea tie-backs for the development of UKCS resources

6 Operators carry at least 5 Subsea technologies in their current Plans, and 11 more Operators report at least 1 technology

This level of interest is commensurate with the number of Operators currently engaged in development of subsea fields

Over 50% of Subsea technologies in Operators’ plans are very recent or still under development, supporting the view that this is one of the most innovative areas of UKCS technologies

Operators can rely on vendors to source advanced subsea design and equipment, as the UK is the base of a world-leading supply chain in this area

Operator-vendor partnerships are also common to develop specific subsea capabilities to address field specific requirements (for instance for HPHT fields)

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Technologies in Pipelines, Risers & Jumpers are focused on cost efficient pipeline manufacturing processes, including adding corrosion resistant linings to carbon steel pipe, use of composite materials and jumper heating for heavy oil. New this year are riser motion sensors and data loggers to continuously monitor riser movements

- Low IR Remedial Technology - Installation of VIPER V-LIFE Low IR insulation resistance recovery technology

- TRL 9 Proven Technologies

- Subsea Control Modules - Subsea Control Module upgrade option to address known obsolescence issues associated with existing units installed subsea

- TRL 9 Proven Technologies

- CSUB subsea equipment protection - GRP Based - Alternative materials solution for Pipeline, Wellhead & Manifold protection structures

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

LinerBridge® has been qualified by DNV GL for use in offshore and onshore applications including towed pipeline bundles and reel-lay. The technology has also been granted approval for use in water injection applications worldwide by Equinor |

Link: TI 22 - 43. Technology Example - LinerBridge - Swagelining Technology.pdf Link: TI 22 - 43. Technology Example - LinerBridge - Swagelining Technology.pdf |

- Combined Flowline and Umbilical - Development group are assessing combined flowline and umbilical technology, potentially including heated systems to enable development of marginal discoveries through reduced costs

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- Remote/Local Jumper Heating- System to provide local heating of subsea jumpers to overcome high viscosity encountered during start up

- TRL 1-4 Early Development

Manifolds, Umbilicals and Control systems have seen an increase in numbers of technologies, doubling since the 2020 survey data. New this year is well & flowline connectivity using re-instrumentation of Xmas Trees & Flowlines to allow reliable, remote visibility of valve positions, pressures and temperatures. Improved instrumentation and new methods of umbilical fault-finding and new generation control systems are also being adopted by Operators.

Other emerging technologies include developing new Subsea Control’s Obsolescence Solutions, Combined Subsea Utilities, Subsea power/comms Using existing umbilical’s with SCM's attached and adding new SCM's with different communications protocols

-

Application of Hydraulic fracturing in Cygnus - 10th infill well is planning to drill a vertical, hydraulically fractured well to develop poor reservoir quality areas. This will be the first application of hydraulic fracturing in Cygnus.

-

TRL 9 Proven Technologies

-

-

Scale Squeeze with Degraded Intervention Barriers – MARS OneSubsea - Scale squeeze deployed from DSV rather than LWIV

-

TRL 9 Proven Technologies

-

| Technology Example: | |

|---|---|

|

CSUB GRP Wellhead protection structure, and Pipeline protection structures |

Link: TI 22 - 44 Technolgy Example - CSUB GRP Subsea Equipment Protection Structures.docx Link: TI 22 - 44 Technolgy Example - CSUB GRP Subsea Equipment Protection Structures.docx |

- C-Kore Subsea TDR unit - The C-kore units will be able to measure insulation resistance, capacitance, continuity resistance, shock & vibration, temperature, and time domain reflectometry. They will be deployed by divers to perform the measurements at respective equipment which are part of the subsea power system.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

The C-Kore Subsea TDR is a compact automated tool for testing subsea electrical assets. It is simple to use, automating the previously complex work of driving a TDR. |

Link TI 22 - 45. Technology Example C-Kore Standalone TDR Unit - Copy.docx Link TI 22 - 45. Technology Example C-Kore Standalone TDR Unit - Copy.docx |

- Well & Flowline Connectivity - Complete re-instrumentation of well Christmas trees and flowlines to allow reliable, remote visibility of valve positions, pressures and temperatures and better shutdown functionality.

- TRL 9 Proven Technologies

- Technip FMC subsea 2.0 Control System - New generation subsea control system

- TRL 5-7 Late Development/Pilot

Ongoing focus on subsea technologies in processing, boosting & storage is reported. The goal is to expand subsea facilities while maximising available platform deck space with subsea processing including subsea gas compression and subsea water treatment, multiphase pumping to enhance tieback distance and wellhead seawater injection using wellhead located pumps.

- Multiphase subsea pumping - Reduce subsea costs and increase reserves through centralised subsea pumping

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

- Wellhead seawater injection - Seawater pump at wellhead to eliminate need for injection water supply system to subsea wells

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

The NOV Seabox™ subsea water treatment module and SWIT™ technology are subsea technologies developed with support and sponsorship from major oil companies. Together they enable treatment of raw seawater directly on the seabed for injection into oil wells for pressure support, improved sweep efficiency, and increased oil recovery. |

Link: TI 22 - 52. Technology Example - NOV Seabox Subsea Water Treatment System.pdf |

- Subsea Gas Compression systems - TotalEnergies looking at Aker OSS gas compression - Reliable gas compression facilities in a subsea environment

- TRL 8 Early Commercialisation

| Technology Example: | |

|---|---|

|

Aker’s Conventional Subsea Gas Compression system includes a subsea separator, motor-compressor and pump units. They are used for high capacity applications. |

Link: TI 22 - 53. Technology Examples - Aker Subsea Compression Systems.docx |

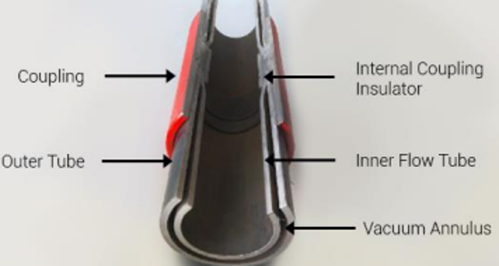

Advances in autonomous vessel design, including both subsea and surface modes of deployment to enable unmanned survey and subsea inspections remotely from the host vessel are reported. Diverless methods of scanning pipelines & risers are also included. New this year are retrofittable corrosion monitoring devices and subsea HPHT vacuum insulated tubing. Emerging technologies include AI for automatic recognition of pipeline features.

- Retrofit Corrosion Monitoring Device Existing system did not give the capability to monitor corrosion or erosion of pipework. Consequently, subsea hardware was retrospectively installed at critical locations and topside software changes implemented

- TRL 9 Proven Technologies

- TRL 9 Proven Technologies

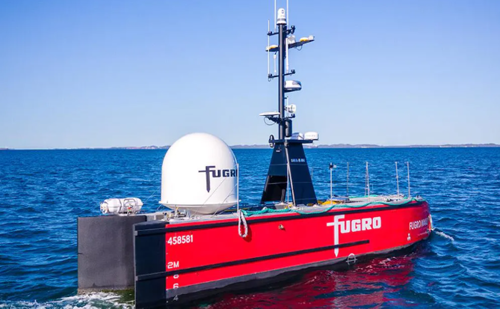

- RAS Autonomous Vessels - Surface and RoV Inspections: Autonomous Surface Vessel acts as a autonomous mothership, carries a 450m depth rated full spec ROV and can be controlled from distant onshore operations centres – reducing both manning and emissions

- TRL 8 Early Commercialisation

| Technology Example: | |

|---|---|

|

Fitted with an electric remotely operated vehicle (eROV), the USV mobilized at the end of April and was controlled from the Woodside-operated King Bay supply facility and Fugro’s remote operations center in Perth, about 1,500 km (932 mi) south of the trunklines. |

Link: TI 22 - 47. Technology Example - Fugro Blue Essence USV.pdf |

- SS Annulus Management Systems. VIT (Vacuum Insulated Tubing) Annulus Management for HPHT Subsea tiebacks

- TRL 8 Early Commercialisation

| Technology Example: | |

|---|---|

|

Vacuum Insulated Tubing can reduce the transfer of heat from produced reservoir fluids into the casing annuli, example proposed for use in subsea HPHT wells. (Helix Offshore example): |

Link:TI 23 - 011 Technology Example - Vacuum Insulated Tubing (VIT) Annulus Management for HPHT Subsea tiebacks.docx |

- ROV Deployed Flexible Scanner - ROV deployed Subsea flexible scanner to identify extent of corrosion to armour wires within flexible pipelines. (Late Development/Pilot)

- TRL 5-7 Late Development/Pilot

- TRL 5-7 Late Development/Pilot

- AI – Using Artificial Intelligence for Automatic Recognition of Features of Pipelines

- TRL 1-3 Early Development