With over 180 technologies reported, and 40% of these in the development or early deployment stage, Reservoir & Well Management is a very active and innovative area in the UKCS technology space.

In 2023, Operators reported new technologies, focusing on hydrocarbon improved recovery, reservoir monitoring, well surveillance, management and intervention. Technologies for Carbon Storage operations were reported for the first time this year.

There has been a high-degree of deployment in the field, thanks also to the partnership between Operators and suppliers in applying these solutions to specific requirements.

Main areas of Operators’ technology focus spreads across design, installation and operational phases of the subsea systems

Advances in pipeline design, and more capable subsea processing equipment enable more distant and cost-effective subsea tie-backs for the development of UKCS resources

There is widespread interest in these technologies, with 12 Operators carrying at least 5 Reservoir and Well Maintenance technologies in their Plans, and 11 more Operators reporting at least 1 technology

There is a balanced mix of technologies at all stages of development in this area, with circa 40% of these being in the development or early deployment stages

Operators rely on vendors to source the majority of technologies, but in circa 35% of the cases participate in the technology development directly and/or in partnership

Readiness definitions: Early Development (TRL 1-4), Late Development/Pilot (TRL 5-7), Early commercialisation (TRL 8), Proven (TRL 9)

Increased adoption of downhole fibre optic sensing for temperature, pressure and vertical seismic profiling. Wireless downhole pressure gauges also reported. Emerging technology includes virtual metering for CCS. New this year are smart monitoring for ESPs and tools for integrated design and operation of subsurface and facilities.

- DAS (Distributed Acoustic Sensing) uses fibre optic technology in a number of new reservoir sensing methods - The Disposable FLI system uses fibre-optic technology to capture distributed temperature and acoustic measurements along the entire length of the well in real time.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

WellSense system uses dis-solvable coated fibre lines attached to a disposable sensing tool The FLI probe and fibre are single-use and sacrificial so can be left in the well at the end of the survey |

|

- DFO (Distributed Fibre Optic), DTS (Distributed Temperature Sensing) and DAS – VSP (Vertical Seismic Profiling - DFO provides understanding on zonal inflow allocation, drawdown optimization, completion integrity and cap rock monitoring and well start-up optimization, VSP technology can be used to augment 4D seismic programmes through the provision of low cost, localised and on demand seismic surveillance.

- TRL 9 Proven Technologies

- Wireless Bottom Hole Pressure Gauges - Downhole pressure monitoring to determine scale deposition at an early stage to mobilize a water wash of the well, also to evaluate salt scaling to optimize waterwash frequency.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Example of this technology from Schlumberger using “Signature gauges” enabled by Muzic acoustic telemetry this technology enables constant communication with the gauges. |

|

- Smart monitoring for ESP (Electrical Submersible Pumps) - Condition based monitoring and automatic optimisation of ESP (Electrical Submersible Pump) wells.

- TRL 9 Proven Technologies

- Energy efficient reservoir drainage (eCalc) - Integrated design and operation of subsurface and facilities - using Operators eCalc tool and worklflow. Enabling improved design and CO2 footprint reduction during operations.

- TRL 8 Early Commercialisation

- Virtual metering - Using Machine Learning for virtual metering and operational envelopes

- TRL 5-7 Late Development/Pilot

- CCS - Collaboration with NZTC on Evaluating the Geological Case for CO2 storage in Depleted SNS Gas Fields. CCS Feasibility study for Operators asset being carried out in house in 2022.

- TRL 1-4 Early Development

An increase in artificial lift technologies including ESPs and gas lift, with a focus on retrofit devices and alternatively conveyed methods. New this year are advanced well and ensemble based reservoir modelling, and acid diverter open path sequence for HT wells. Emerging technologies include downhole compression and digital well book.

- Alternate Conveyed ESP’s/Slimline ESP’s – Remedial ESP’s deployed by coil/cable, Investigation and field trial of alternate deployed (e.g. coil/cable), remedial ESP systems, alternate motors (e.g. permanent magnetic)

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

The thru-tubing ESP is deployed through a surface lubricator and lowered inside the existing production tubing. Easily retrieved using only the cable. |

|

- IGLS Inverse Gas lift System - enables IGLS installation in wells that have not been configured for conventional gas lift,

- TRL 9 Proven Technologies

- Velocity String – In depleted field with lack of motive power to produce, Through Tubing Velocity String installation to surface with new approaches to utilising the SSSV Proprietary Gas lift system

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Example of this technology from Schlumberger using “Signature gauges” enabled by Muzic acoustic telemetry this technology enables constant communication with the gauges. |

|

- Advanced well modelling - Tool for modelling wells with inflow control technology, including options for modelling impact of annular flow and zonal isolation

- TRL 9 Proven Technologies

- Multistage propped fractures - Modelling of frack opportunities within Columbas and Ninian Slumps using Calgary in-house software and expertise

- TRL 9 Proven Technologies

- Acid Diverter Open Path Sequence - Effectively treat heterogeneous reservoir layers in HT well.

- TRL 8 Early Commercialisation

- Ensemble-based reservoir modelling - Employed (Resoptima ResX) ensemble-based reservoir modelling to build an ensemble of forecast models to drive improved field management and field development decision making.

- TRL 9 Proven Technologies

- Downhole Compression - Maximising recovery from old gas fields and weaker wells is proving an increasing challenge as the field ages. The conventional methods of dropping the topsides separators pressures only get so far and then using surfactants to lift liquid loaded wells, also has limits and eventually least to COP from the well.

- TRL 5-7 Late Development/Pilot

- Digital Well Book – Integration in one single tool of all well information and workflows to determine well potential, compare performance against forecast, register and rank opportunities for improvement.

- TRL 1-4 Early Development

Operators are adopting technologies for improving well access for interventions and low-cost workover rigs to reduce the costs. New this year is the WellTech puncher/cutter multifunction wireline tool & real time coiled tubing.

- OneSubsea MARS* multiple application reinjection system serves as a universal interface for trees (topside and subsea), enabling processing equipment to be installed between the existing isolation barriers, thus eliminating the need for challenging intervention.

- TRL 9 Proven Technologies

- WellTech Puncher / Cutter - slickline deployed cutter and stroker. Puncher and cutter can be deployed in a single string

- TRL 9 Proven Technologies

- Dwellop’s Lynx Mast – The DWELLOP Lynx WireLine Mast is designed to improve wireline mast operations on fixed offshore installations. It improves access, rigging time and safety for personnel – enabling safe and efficient wireline operations.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

The new 90’ LynxTM Wire Line Mast is setting a new industry standard. Introducing superior efficiency, increased working environment and without the need for external cranes once installed. Also features BOP access in compliance with Norsok S-002. |

|

- Wellvene’s WellHop lightweight wireline system, - Full wireline spread takes minimum 6 POB, typically 48 hours+ to rig up and ~24 hours to move between wells. This puts strain on platform schedule/manning the WellHop system is lightweight, unitized and designed for minimum rig up/down time.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

WellHop system is lightweight, unitized and designed for minimum rig up/down time, and reduce manning requirements. |

|

Other Technologies in this sub-category include: Wireline Technologies such as WellAnt Abrasive Cutting tool for well bore obstructions, Razor multi-purpose tool to bridge plugs, stroker, punch and cutter Rigidlock Deepwater wellheads.

- Flow Assurance Module (FAM) – A valve manifold module fixed on the annulus side of the Xmas tree to allow injecting scale inhibitor down to the well without breaking tree cap. This allowed Anasuria to use ROVSV rather than LWIV for scale squeeze with less intervention days.

- TRL 5-7 Late Development/Pilot

Well Integrity repairs continue to show strong innovation in providing solutions for wellhead leakages, tracking well leak paths and tubing retrievable/retrofit SSSVs, and Storm Chokes for HPHT wells. New this year are water shutoff annular isolation technologies, swellable seals and slim pump safety valves. Emerging technology includes DHSV control line remediation by nano coil.

- Novel wellhead sealing for production wells due to integrity issues - A time activated sealant is deployed in its liquid phase into the voids of wellhead sealing areas. Once in place, the sealant converts to a resilient, self-bonding and pressure-energized solid material.

- TRL 9 Proven Technologies

- HPHT Storm Choke - Pressure dependent valve to replace failed SSSV operation

- TRL 9 Proven Technologies

- Oilenco React Swellable seals - Oilenco React swellable seals used when gas influx is seen in wireline retrievable SSSV control line. Polished bore of safety valve landing nipple can be damaged and this seal swells in oil or water, creating a seal in the damaged area

- TRL 9 Proven Technologies

- Slim Pump Safety Valve (SPSV) - The Slim Pump Safety Valve can be incorporated into Cable Deployed ESP's or Jet Pump Systems, providing an API qualified valve with minimal additional system complexity.

- TRL 9 Early Commercialisation

- TRL 9 Early Commercialisation

- Tendeka PulseEight Electronic Ambient Valve (EAV) - In wells with an inoperable DHSV that require a replacement to be brought online where a normal DHSV cannot be used. E.g. control line issues, access issues etc. Tendeka PulseEight Electronic Ambient Valve (EAV).

- TRL 8 early Commercialisation

- Wireless Downhole Safety Valve - SLB’s retrievable wireless subsurface safety valve system helps operators restore wells and resume production after SSSVfailure in – producing and injectionwells.

- TRL 8 Early Commercialisation

| Technology Example: | |

|---|---|

|

Schlumberger – Wireless Downhole Safety Valve : wells that require remediation after a (TR-SSSV) failure, or wells originally completed without a subsurface safety valve and now requiring one due changes in policies or regulations |

|

- DHSV Control line remediation “Nano Coil” - DHSV control lines run behind the tubing in a well - but can be a direct conduit to the reservoir if barrier failures occur. Repairs of these can be completed using sealant for low rate leaks, however other currently unable to resolve intrusive issues. Nano-coil for deployment into DHSV control lines.

- TRL 5-7 Late Development/Pilot

This sub-category is showing more innovation this year with deployable technologies using mechanical, radio frequency signals & electro-hydraulic pulsing technologies, Emerging technology includes use of kinetic hydrate inhibitors. New this year are innovative solutions to inhibit and soften wax and asphaltenes.

- Innovative wax Inhibitor and dissolver - green carbon electron sharing technology that weakens the Van der Waals attractive forces for Asphaltenes and paraffins allowing a phase change from solid to liquid that effectively controls waxes and asphaltenes at a lower dosage rate both inhibits and dissolves wax“

- TRL 9 Proven Technologies

- Exothermic reactive chemical - wax dissolver - This is an exothermic reactive chemical upon mixing of organic acid and base at certain ratios to achieve temp required to dissolve wax

- TRL 9 Proven Technologies

- SPIN tool Technology - The SPIN device is a mechanical scale prevention tool developed by Scale Protection. It prevents scale from growing across the safety.

- TRL 9 Proven Technologies

- ClearWell - Scale build inhibitor - ClearWELL™ is a surface mounted scale control technology which transmits radio frequency signals along production tubing.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

ClearWell examined five North Sea wells and made recommendations for how ClearWELL™ technology could address their calcite scaling. And subsequently installed ClearWell system on the platform. |

|

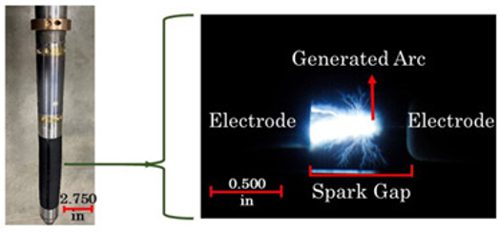

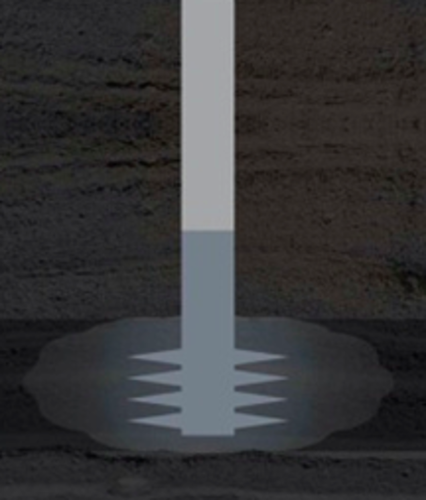

- Wireline deployed scale removal tool - BlueSpark WASP - Wireline deployed high pulse tool for scale removal and production stimulation using Electro-Hydraulic Pulsing (EHP) principles

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Bluespark WASP - Wireline deployed high pulse tool for scale removal and production stimulation |

|

- Small Footprint Coil - Small footprint coil tubing for removing salt/scale at HT & depth>16,000ft

- TRL 5-7 Late Development/Pilot

- Kinetic Hydrate Inhibitor’s- Prevents the creation of hydrates - allowing for better flow along the pipeline - Kinetic hydrate inhibitors (KHIs) interfere with hydrate crystal growth or nucleation by embedding themselves into the lattice structure, delaying significant growth for longer than the fluid’s residence time

- TRL 5-7 Late Development/Pilot

- Ultrasound Based Technology for removal of scale from downhole production tubing - Removal of Scale in a safe, quick and economical way to maximise recovery from wells with a tendency to scale. Ultrasound Based Technology for Removal of Scale from Downhole Production Tubing

- TRL 1-4 Early Development

This sub-category includes a range of new products to improve flow and trace the production geology of reservoirs. Emerging technologies include improving well water and liner shut off, together with rejuvenation techniques for shut in wells and water shutoff by annular isolation technologies and expanding polymer grains.

- Drag Reducing Agent (DRA) injected into seawater stream to increase water injection volumes

- TRL 9 Proven Technologies

- Rejuvenation of shut-in wells - wells are shut-in due to liquid loading or sand/proppant fill. A well was restarted successfully by controlling the drawdown of the formation to avoid water coning

- TRL 9 Proven Technologies

- Water tracers - Allowing identification of open perforations and also the early identification of water breakthrough from individual zones –

- TRL 9 Proven Technologies

- Water Shut Off – BISM (Isol8) or Resin based CANNSeal Annular Isolation Technology - .

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Annular isolation sleeve by Isol8 - Designed to be run on casing/liner like a centraliser. Left in situ and then melted at well decom stage for annular isolation or when well shows annular integrity issues during production |

|

- Resolute Expanding Polymer Grain Pumped into the reservoir to make it expand and fully block permeability, it provides a barrier to barrier, self- healing seal surrounding the wellbore.

- TRL 5-7 Late Development/Pilot

| Technology Example: | |

|---|---|

|

Resolute Expanding Polymer Grain Pumped into the reservoir to make it expand and fully block permeability, it provides a barrier to barrier, self-healing seal surrounding the wellbore. It blocks perforations, screens & bore space providing a self-healing pre-barrier to plugs and cement |

|

- Horizontal Well water shut off - A study showed the most applicable technologies to use are mechanical plugs to achieve a seal in the wellbore and highly thixotropic polymer gels to achieve a seal in the annulus

- TRL 1-4 Early development

- Deployment of snorkel on wireline - Design of different connector to allow deployment of snorkel on wireline rather than coil

- TRL 5-7 Late Development/Pilot

Sands & Solids Management sub-category reported technologies including retrofittable downhole sand screens, porous foam and oil-based gravel packing. Emerging technologies include low-cost sand control completions and EHS screens. No new technologies reported in this sub-category for this year.

- Dual string perforating and retrofitting downhole sand screens - Interventions in two wells during 2020 to shut-off water from the lower reservoir, and access attic oil behind the production casing. The latest perforating technology was tested to achieve the required penetrations of the tubing and production casing set across the upper reservoir section. Downhole sand control using 3M ceramic will be deployed - as conventional steel screens would likely be cut by the velocity of production through the perforated tubing/casing.

- TRL 9 Proven Technologies

| Technology Example: | |

|---|---|

|

Ceramic sand screens from 3M showed enhanced longevity in comparison with Steel screens in an extreme hardness erosion test. The 3M Ceramic Sand Screen Systems were more resistant to chemical attack by fluids such as hot sulfuric acid, aggressive completion fluids and other corrosive chemicals used in the oil and gas operations industry |

|

- GeoForm - Porous foam that set around liner for sand control

- TRL 9 Proven Technologies

- Oil Based (NAF) Gravel Packing - Increased productivity in low net to gross reservoirs

- TRL 9 Proven Technologies

- Reliable low-cost sand control completion - Evaluate alternative sand control completion designs that are reliable and maintain recovery, enable the development of reservoir targets that are marginal currently - maximise economic recovery, extend field life.

- TRL 5-7 Late Development Pilot

- Endurance Hydraulic Screen Solution - New screen filter development for EHS solution that will enhance screen productivity

- TRL 1-4 Early development